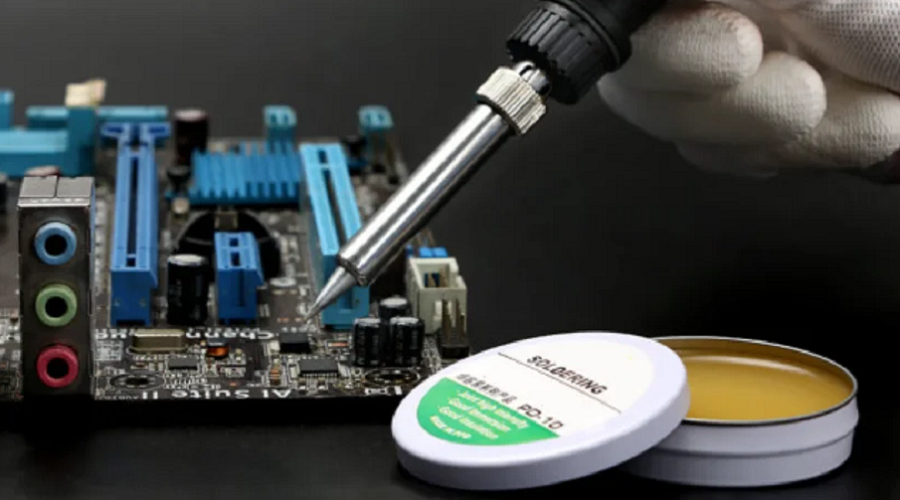

Flux for Soldering

Flux is a vital component used during soldering with soldering irons or soldering stations. It enhances activity and dissolves solder on the surface. AMTECH NC-559 and RMA-223 are popular flux brands suitable for phone repair, enabling soldering and desoldering processes.

-

AMTECH NC-559 Lead-Free Solder Flux: This lead-free solder flux paste is specifically designed for cell phone BGA and PCB repair. It offers exceptional wetting properties, reducing the occurrence of solder defects. Repair professionals value AMTECH NC-559 for its reliability, consistency, and compatibility with mobile phone repair tasks.

- RMA-223 Solder Paste Flux: Widely used in phone repair, RMA-223 is a leaded solder paste known for its excellent thermal stability and flux activity. With good soldering performance and reliable joints, RMA-223 is suitable for various mobile phone repair applications, making it a trusted choice among repair technicians.

Rosin Flux

Rosin flux is another commonly used soldering aid that increases the melting and soldering capabilities of the soldering iron tip. Mechanic X6, X8, and X9 are well-known brands of rosin flux. These fluxes are suitable for soldering tasks during phone repairs.-

Mechanic X6/X8/X9 Rosin Flux: This rosin-based soldering iron paste flux is specifically formulated for phone soldering and repair. It exhibits excellent wetting characteristics, minimizing the occurrence of solder bridges and cold solder joints. The high-quality formulation and ease of use make Mechanic X6/X8/X9 Rosin Flux ideal for precise mobile phone repairs.

-

Mechanic Rosin-Based Tin Flux Paste Cream: This rosin-based tin flux paste cream is designed for phone PCB welding repair. It offers excellent flux activity and soldering performance, ensuring reliable and durable connections. Repair technicians appreciate Mechanic Rosin-Based Tin Flux Paste Cream for its versatility and effectiveness in resolving common soldering issues encountered during mobile phone repairs.

Repair Flux

Repair flux is used to supplement soldering during chip replacement. Mechanic UV223 and AMTECH NC-559 are commonly used repair flux brands. These fluxes are used for soldering tasks during chip replacement in phone repairs.-

Mechanic UV223/559 Lead-free Solder Paste Flux Welding Oil: This lead-free solder paste flux is specifically formulated for chip soldering and repair in mobile phones. It provides excellent wetting and flux activity, ensuring reliable solder joints. The solder paste is suitable for tin-filling operation when the tin chip is implanted.

The ease of use and precise application capabilities of Mechanic UV223/559 Lead-free Solder Paste Flux Welding Oil make it a valuable tool for efficient and accurate chip soldering during mobile phone repairs.

The ease of use and precise application capabilities of Mechanic UV223/559 Lead-free Solder Paste Flux Welding Oil make it a valuable tool for efficient and accurate chip soldering during mobile phone repairs.

- 183℃ (high temperature)

- 158℃ (medium temperature)

- 138 ° C (lead-free)

- 217℃ (lead-free)

Solder Flux-Related Issues and Solutions

1. Excessive flux residue:Cause: Using too much flux during soldering.

Solution: Apply an appropriate amount of flux and clean the residue thoroughly.

2. Inadequate flux activation:

Cause: Improper or insufficient activation of flux.

Solution: Use compatible flux, properly activate it with even heat, and control soldering temperature.

3. Flux spattering:

Cause: Rapid heating or excessive flux on the soldering iron.

Solution: Heat gradually, clean the soldering iron tip, and consider using low spattering flux.

Remember, proper flux application and activation are essential for achieving reliable solder joints. Follow the instructions for the specific flux you are using, and practice good soldering techniques to minimize flux-related issues.

Also Read: Common Soldering Station Accessories and Cleaning Tools

Work with a Manufacturer You Trust

1 comment

Rajkumar Kale

This article offers valuable guidance on selecting the appropriate solder paste for repairing phone motherboards, catering to both beginners and experienced technicians. By outlining key factors such as alloy composition and flux type, it empowers readers to make informed decisions based on their specific repair needs. The clear explanation of different solder paste characteristics facilitates understanding, making it easier to choose the right one for each repair task. Additionally, the inclusion of practical tips enhances the article’s usefulness, ensuring a smoother repair process for enthusiasts and professionals alike. Overall, it’s a comprehensive resource that aids in achieving successful phone motherboard repairs with the right solder paste choice.