Qianli Super Cam X 3D thermal camera parameter:

Resolution: 52000(260x200)

Wavelength Range: 7-14um

Camera Angle: 42x32

Input voltage: 5V DC

Power consumption: <259mw

Display mode: infrared thermal imaging

Interface Type: USB type C

Picture Storage format: JPG(640x480)

Video storage format: MP4

Temperature measurement: Full-scale temperature measurement

Temperature measurement distance: 2mm-

Temperature measurement accuracy: +-5%

Temperature measurement range: -20-120

Operation system: WIN10/7

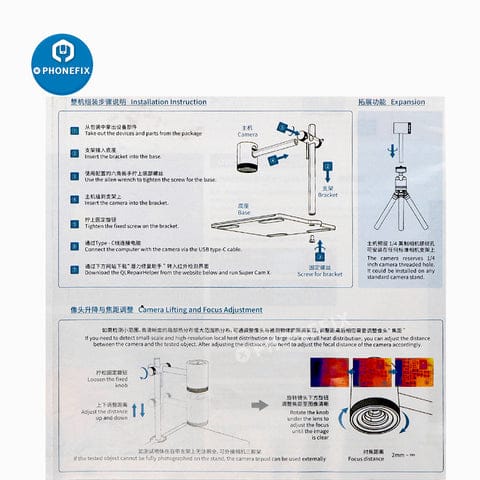

1. How to install the 3D thermal camera?

- Insert the bracket into the base

- Tighten the bottom screws with a wrench

- Insert the camera into the bracket

- Tighten the fixed screw on the bracket

- Connect the 3D thermal camera to the computer via USB type-c cable.

- Download the software. (https://www.qianlispace.com/index/download/index.html)

2. How to use the 3D thermal camera?

Download the software, register your account and select Super Cam X to run the software.

- Click "Thermal imaging" to switch the interface

3. The functions of the software

- Connection status and ID display

Green: the device is connected.

Red: the device is disconnected.

Device ID: shows the SN of the current connected device

- Thermal imaging color palette switch

Click the icon to switch different thermal imaging color palettes, different color palettes are suitable for different application scenarios.

- Image rotation and flip switch

When necessary, you may click the rotate or flip icon to change the image direction to suit the target objects.

- Device tutorial and configuration

CLick the tutorial icon to pen the instruction, or you can scan the code to get the instruction

- Software configuration

Turn on/off the Mouse Temperature unit, Alarm Sound, Alarm duration, adjust 3D comparison level and Fix Temperature Range, change pictures folder and videos folder location.

Parameter Correction is only for very professional engineers.

- Thermal Image

Thermal image area, all the features aren results will be displayed in this area, if the thermal image is not sharp enough, please adjust the lens to get clear focus.

The zone area features(eg 14,15) need secondary operation in this area.

- Temperature adjustment

This function is the core function, drag the dot to adjust the temperature range, which can locate the imperceptible short-circuit leakage problem

- Language

Available in Chinese, English and Spanish.

- Captured image and screen recording preview

- Analysis mode switch

- Video, capture, reset screen.

- High temperature alert/tracking

- Temperature curve of the rectangular and polygonal area

- Rectangular area temperature, regional detailed inspection, text mark.

- Electricity leakage quick check

4. Mode

- PCBA quick diagnosis (Printed circuit board assembly)

This mode is focused on the PCBA defect troubleshooting and repair, by pressing the button "Electricity leakage quick check" of the 3D thermal camera to increase the contrast of the image, and adjust the temperature range, to quickly locate the PCBA short circuit and electricity leakage,etc. It can detect the minimum 6mA electricity leakage.

Fault location method: Place the PCBA under the lens and adjust the lens focus then get a clear image, power on the PCBA, press the button "Electricity leakage Quick Check" to quick locate the fault, if the electricity leakage current is too small, you may adjust the temperature range to increase the contrast of the image.

- Thermal imaging field distribution

This mode is focused on thermal imaging field distribution of the product and PCBA, such as PCBA layout heat evenly distribution and product heat dissipation efficiency ect. (3D/2D)

- Comparison

This mode is to optimize the heat distribution design, defect and working PCBA analysis, to compare the defect to the working PCBA to locate the defect.

- Professional mode

The professional mode is for new professional functions expansion, and it's not open yet.