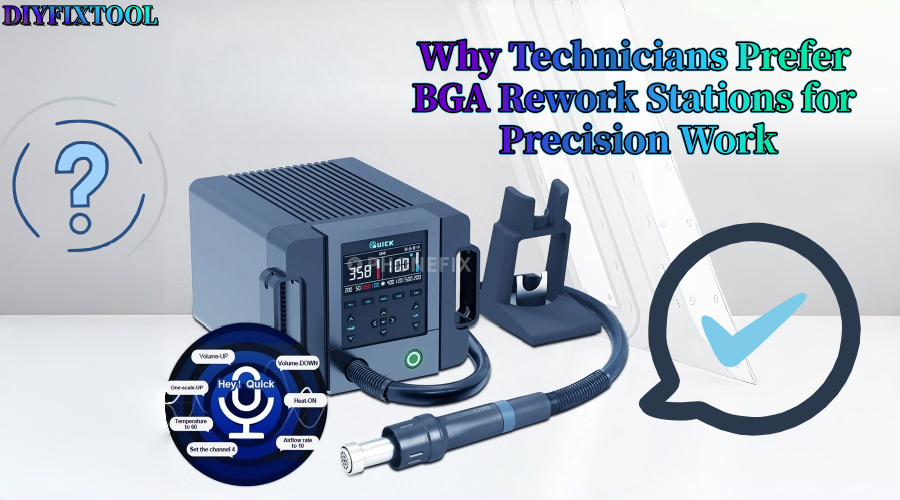

As modern technology repair and electronic device maintenance increasingly move toward high precision and miniaturization, quick rework stations have become the preferred tool for technicians handling various miniature components. DIYFIXTOOL explores the definition, functionality, and advantages of rework stations, particularly their applications in mobile phone repairs.

I. BGA Rework Station Overview

A BGA rework station is a specialized tool for repairing electronic defects and desoldering or soldering small components. With advancing technology, it has become essential for technicians, especially in repairing high-precision devices like phones, laptops, and tablets.

· Core Functions

1. Temperature Control System

BGA Rework Stations precisely control the heating element's temperature, preventing overheating or insufficient heating that could damage components.

2. Airflow Control

With adjustable airflow settings, rework stations let technicians manage airflow to protect sensitive components from high-temperature damage.

3. Automatic Cooling System

After heating, the automatic cooling system rapidly lowers the temperature, extending equipment life and preventing overheating hazards.

II. Advantages of BGA Rework Stations

BGA rework stations have become the tool of choice for technicians worldwide due to several irreplaceable advantages:

1. Adjustable Temperature Control

Each electronic component requires a specific temperature for soldering or desoldering. High temperatures can burn components, while low temperatures may weaken solder joints. The adjustable temperature control of rework stations allows technicians to fine-tune settings, ensuring precision and safety during repairs.

2. Precise Airflow Control

BGA rework stations offer precise airflow control, preventing damage from strong airflow and improving efficiency with weaker airflow, ensuring better soldering success rates.

3. Enhanced Work Efficiency and Precision

BGA rework stations have high-performance control systems that allow technicians to solder and desolder with speed, precision, and reliability, reducing errors and improving productivity. BGA rework stations save time and reduce mistakes, making them ideal for tasks like iPhone battery connection soldering repairs, where precision and careful handling are crucial.

III. Practical Applications

Quick rework stations are widely used in various precision tasks, especially in the repair and assembly of electronic devices. Below are some common applications:

1. Mobile Phone Repairs

Mobile phone repair is one of the most significant applications of modern rework stations. As smartphone technology advances, the internal electronic components of mobile phones have become smaller and more complex. Rework stations play a vital role in the following tasks:

· Desoldering Small Components: Components like capacitors, resistors, and chips on mobile phone circuit boards often require precise desoldering. The temperature and airflow control features of quick rework stations enable technicians to control the desoldering process accurately, preventing damage to the components.

· Replacing Faulty Components: For faulty components on the mobile phone circuit board, technicians use the rework station to heat, desolder, and replace the defective component, restoring functionality. Paired with Precision tweezers, technicians can handle small components with care, ensuring a clean, controlled process without damaging surrounding parts.

2. Electronic Device Repairs

In addition to mobile phones, quick rework stations are widely used in the repair of other electronic devices. Whether it's laptops, tablets, or televisions, rework stations help technicians accurately address circuit board defects and perform soldering and desoldering tasks with high precision.

3. High-Precision Electronic Device Assembly

During the assembly of high-precision devices like robots and medical equipment, the fine soldering capability of rework stations ensures each component fits perfectly, maintaining the device's stability and functionality.

IV. Comparison with Traditional Soldering Tools

1. Precision and Control

Traditional soldering tools lack precise temperature and airflow control, making accurate repairs difficult. BGA rework stations offer precise control, ensuring high-precision repairs, especially for miniature components.

2. Automation and Efficiency

Traditional tools rely on manual control, lowering efficiency. BGA rework stations feature automatic cooling and intelligent controls, boosting productivity and minimizing intervention.

3. Operational Safety

Traditional tools may cause component damage due to improper handling, leading to higher repair risks. The precise control in quick rework stations minimizes the risk of damage, ensuring the safety of both the equipment and the iPhone Components.

V. Conclusion

In conclusion, quick rework stations offer technicians precise and reliable tools for repairs, with superior temperature control, airflow adjustment, and automatic cooling. Their exceptional performance makes them the top choice for technicians globally.If you are looking for a reliable quick rework station or want to learn more about the latest technologies and trends in mobile phone repair, feel free to visit the DIYFIXTOOL website.